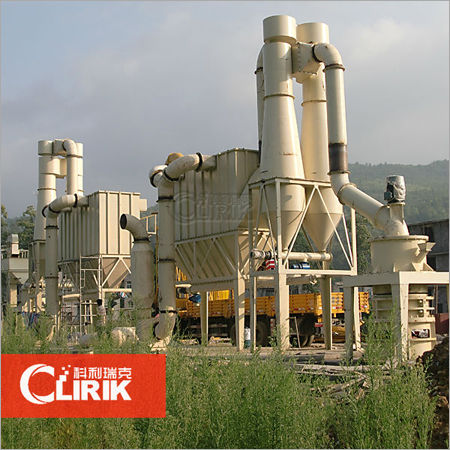

Kaolin Grinding Mill Machine

Product Details:

- Model KGM-500

- Rotation Clockwise

- Product Type Grinding Mill Machine

- General Use Grinding Kaolin Mineral

- Material Mild Steel

- Type Surface Grinding Machine

- Capacity 300 kg/hr

- Click to View more

Kaolin Grinding Mill Machine Price And Quantity

- 1 Unit

- 9999 USD ($)

- Onsite & Remote Support

- Automatic Centralized

- Mining, Ceramic, Paper, Rubber

- <75 dB

- Heavy Duty Welded Steel

- Emergency Stop, Overload Protection

- <20 mm

- Water Cooling

- Floor Mounted

- 80-425 mesh

Kaolin Grinding Mill Machine Product Specifications

- No

- 2.2 kW

- 2850 rpm

- 1350 x 1000 x 1700 mm

- Mild Steel

- Surface Grinding Machine

- 1350 x 1000 mm

- Grinding Mill Machine

- 1200 kg

- 500 mm

- Manual Control

- 250 x 500 mm

- 40 L

- High Precision, Low Noise

- 200 x 20 x 31.75 mm

- Grinding Kaolin Mineral

- Semi-Automatic

- 380 V

- Green

- KGM-500

- 250 x 500 mm

- Clockwise

- Double V Type

- 2850 rpm

- 300 kg/hr

- Not CNC

- Onsite & Remote Support

- Automatic Centralized

- Mining, Ceramic, Paper, Rubber

- <75 dB

- Heavy Duty Welded Steel

- Emergency Stop, Overload Protection

- <20 mm

- Water Cooling

- Floor Mounted

- 80-425 mesh

Kaolin Grinding Mill Machine Trade Information

- 1000 Unit Per Month

- 15 Days

Product Description

Types of Kaolin Grinding Mill Machine

five models HGM80 HGM90 HGM100 HGM125and HGM1680L

finished production fineness 250meshes2500meshes 574 micron

the capacity tonhour ranges from 04TH to 45TH

Kaolin Grinding Mill Machine has been widely used in making fine powder or micro powder CLIRIK Kaolin Grinding Mill Machine is applicable to nonflammable and nonexplosive materials with hardness less than 6 such as the calcite chalk limestone dolomite kaolin bentonite talcum talc magnesite illite pyrophyllite vermiculite sattapulgite rectorate diatomite barite gypsum alum earth graphite fluorite variscite potash ore floatstoneetc

As one of the best Kaolin Grinding Mill Machine manufacturers CLIRIK has developped and manufactured more and more advanced grinding machine The supermicro grinding mill is kind of popular micro milling machine The ultrafine mill is invented by absorbing advantages from the same trade home and abroad

Working principle of Kaolin Grinding Mill Machine

After crushed by hammer crusher the large materials are crushed into small ones and sent to storage hopper by elevator and then evenly sent to the upper distribution plate of the turnplate by vibrating feeder and sloping feeding pipe

When the Kaolin Grinding Mill Machine is at work all the grinding rollers are rolling in the ring and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed crushed and grinded by the rollers

The highpressure air blower constantly inhales air within the Kaolin Grinding Mill Machine and in turn the airflow with crushed materials are brought to the classifier whose highspeed impeller will screen the airflow the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector Most of the qualified powders will fall and exit from the discharging valve at the bottom a small proportion of the fine powders with airflow moves to the dust cleaner and clings to the surface of the filter bags At the same time the fine powders clinging to the surface fall down by the sudden vibration of the filter bags which is caused by the instantly ejected highpressure gas controlled by the pulse valve The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed In addition filtered clean air will be emitted from the air outlet of muffler in the end

Kaolin Grinding Mill Machine Features

This Kaolin Grinding Mill Machine is of lots features and benefits such as the high efficiency in same condition of finished particle size and power of motor The output of the micro milling machine is 40 higher than airflow mill and whisk mill In same condition of material and finished particle size the quickwear part of the Clay Grinding Mill is of high using rate and longer lifetime than traditional milling machine Because there are no axle tree and bolt in the grinding an trum there will be no wear out of bearing and sealing part and also no loose of bolts which will greatly improve the safety of the Kaolin Grinding Mill Machine Whats more the Clay Grinding Mill will greatly lighten polution and noise by using dust cleaner and muffler which has achieved environmental protection requirement

Superior Performance for Diverse Applications

Designed for high-precision kaolin grinding, the KGM-500 excels in mining, ceramics, paper, and rubber sectors. Its robust construction and powerful 2.2 kW motor enable smooth, efficient operations, while advanced water cooling maintains temperature stability during prolonged use. With floor-mounted installation, the machine integrates seamlessly into production lines, delivering enhanced grinding accuracy and reliability. The wide discharge fineness range allows flexibility for various production needs.

Advanced Safety and Noise Control

Prioritizing operator safety, the machine features an emergency stop button and overload protection systems. Its noise level stays below 75 dB, minimizing workplace auditory discomfort. The centralized automatic lubrication system ensures consistent maintenance, prolonging machine life. Built with high-grade mild steel, the heavy-duty frame promises operational durability and minimal vibration for precise grinding results.

FAQs of Kaolin Grinding Mill Machine:

Q: How does the Kaolin Grinding Mill Machine achieve high precision in grinding?

A: The KGM-500 utilizes a double V type table slide way and operates at 2850 rpm to guarantee stable movement and consistent surface finish. The grinding wheel spins at high speed, enabling discharge fineness between 80-425 mesh for precise, uniform kaolin particle sizes.Q: What materials and industries is this grinding mill best suited for?

A: This machine is specifically designed to grind kaolin minerals and is widely used in mining, ceramic, paper, and rubber industries, offering reliable performance across various application areas that require fine kaolin powders.Q: Where should the Kaolin Grinding Mill Machine be installed for optimal operation?

A: Best installed in a well-ventilated industrial setting with access to a stable power supply (380 V), the floor-mounted design and compact footprint (1350 x 1000 mm) ensure it fits easily into existing production environments.Q: What safety features are included in the Kaolin Grinding Mill Machine?

A: Operator safety is ensured with an emergency stop button and built-in overload protection. These features protect both the user and the equipment during unexpected situations or excessive load conditions.Q: How is the lubrication and cooling process managed in this machine?

A: The KGM-500 is equipped with an automatic centralized lubrication system that maintains critical moving components. Water cooling efficiently dissipates heat, ensuring stable operation and preventing overheating during continuous use.Q: When is after-sales support available for this machine?

A: Both onsite and remote after-sales support are offered by the manufacturer after installation. Users can access technical assistance and troubleshooting at any stage during the machines operational life.Q: What are the benefits of using the KGM-500 model for kaolin grinding?

A: Benefits include high grinding capacity (up to 300 kg/hr), low noise operation (<75 dB), high precision, automatic lubrication, robust construction, and safety features that collectively enhance productivity and operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese