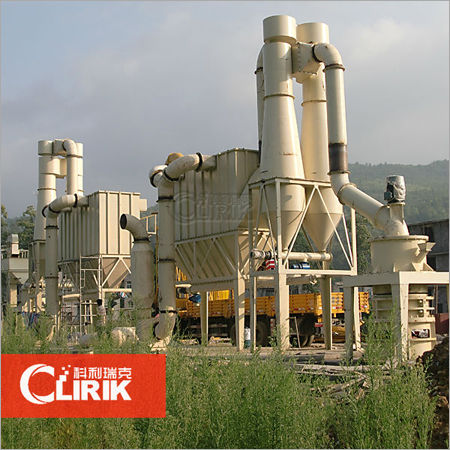

Dolomite Grinding Mill Machine

Product Details:

- Model DGMM 3200

- Rotation Clockwise or Counterclockwise

- Product Type Grinding Mill Machine

- General Use Grinding Dolomite Stone to Powder

- Material Mild Steel/Alloy Steel

- Type Raymond Mill / Ball Mill / Vertical Mill (per order)

- Capacity 1-40 TPH (Depends on Model)

- Click to View more

Dolomite Grinding Mill Machine Price And Quantity

- 1 Unit

- USD ($)

Dolomite Grinding Mill Machine Product Specifications

- Grinding Dolomite Stone to Powder

- 3200 mm x 1500 mm x 2000 mm

- Precision Slide Way

- Grinding Mill Machine

- Not CNC

- 1440 RPM

- Depends on Model (Typical: 2000 mm)

- N/A (Electric Powered)

- 37 kW

- 1-40 TPH (Depends on Model)

- Varies by Model

- Mild Steel/Alloy Steel

- 6500 kg

- High Efficiency/Low Power Consumption

- 1500 RPM

- Manual Control

- DGMM 3200

- Grey/Green/Blue (Customized)

- Standard Size

- No

- Clockwise or Counterclockwise

- 3200 mm x 1500 mm x 2000 mm

- Semi-Automatic

- Raymond Mill / Ball Mill / Vertical Mill (per order)

- 380 V

- Depends on Model (Typical: 800 mm - 1200 mm)

Dolomite Grinding Mill Machine Trade Information

- 1000 Unit Per Month

- 15 Days

Product Description

Production description of dolomite grinding mill machine

Brand CLIRIK

Model HGM80 HGM90 HGM100 HGM125 and HGM1680L

Capacity 04 30th

Input size 20 mm

Finished size 1502500 meshes 5100 micron

Power 123430 kw

Warranty aone year against manufacturing defect boffer lifetime consultation on problems occurred

Features

High Efficiency

Long lifecycle of spare parts

High safety and reliability

High fineness flexible adjustment

Environmentfriendly

Application of dolomite grinding mill machine

HGM Series dolomite grinding mill machine specializing in producing fine and super calcium carbonate powder of noninflammable nonexplosive and brittle materials with Mohs hardness under six such asvermiculite vermiculite and vermiculite calcium carbonate powder calcium carbonate powder calcium carbonate powder calcium carbonate powder calcium carbonate powder rock phosphate phosphate serpentine etc totally more than 100 kinds of materials

Working Principle of dolomite grinding mill machine

The main bearing and each dial are driven by electro motor of main machine through reducer and numbers of rollers which are rolling in the ring are driven by dial through plunger After crushed by hammer crusher the big materials become small ones and are sent to storage hopper by elevator and further sent to the middle of first dial evenly by the electromagnetic vibrating feeder and feeding pipe The materials will be driven to the edge of dial by centrifugal force and fall down into the ring crushed and grinded by roller and become powder after production of three rings The high pressure centrifugal blower will inhale air from outside and blow the crushed materials to classifier The rotating turbo in the powder concentrator will make the coarse material return to the mill and reground while the fineness will mix with the air and go into the cyclone and be discharged in the discharge bin which is at the bottom of it The air which mixed with very little fineness will be purified by impulse duster and discharged by blower and muffler

Technical specification of dolomite grinding mill machine

Model HGM80 HGM90 HGM100 HGM125 HGM1680L

Ring Diametermm 800 900 1000 1250 1680

Ring Number PCS 3 34 4 4 4

Roller NumberPCS 1821 2429 2836 3044 3040

Main Shaft Speed r p min 230240 200220 180200 135155 120130

Input Size mm 010 010 015 015 020

Finished Size ummesh 745

2002500 745

2002500 745

2002500 1006

1502000 1009

1501500

Capacity th 0445 0665 19 216 3830

Outlet Size LWH m 139462 1474872 184686 1491025 26375119

Unit KW HGM80 HGM90 HGM100 HGM125 HGM1680L

Main Unit 5575 245 132 185200 315

Classifier 185 185 30 37415 5185

Blower 45 55 75 245255 275290

Crusher 185 185 185 45 75

Bucket Elevator 3 3 4 4 75

BeltConveyor Feeder 22 22 22 3 3

Spiral Conveyor 3 3 34 23 255

Discharging Valve 2075 1075 111 211 211 2075215

Air compressor 11 15 22 21537 55

Remark

For the data with prefix such as 2xxit means there are two motors 2075configuredfor one item Forexampledischarging valveHGM80 with configuration it means there are 2 pieces of 075KW motors installed with discharging valve

Note This specification is just referencing any changes are subject to the products

High-Efficiency Grinding Performance

The Dolomite Grinding Mill Machine excels in producing finely ground dolomite powder, supporting output fineness from 80 to 400 mesh for diverse industrial applications. With its substantial power capacity and automatic/manual lubrication options, it maintains consistent output while minimizing downtimes. Its main shaft speed and adjustable working speed provide flexibility to match varied production needs, ensuring optimal grinding for both small and high-volume operations.

Robust Construction and Safety Standards

Built from either mild or alloy steel, the DGMM 3200 model is engineered for durability and reliable operation. Advanced safety features such as an emergency stop and full protective guarding maintain operator protection during use. The machine is floor-mounted and designed for stable placement, allowing safe and efficient functioning in demanding environments like mining and construction sites.

Versatile Applications and Simple Control

Suitable for industries such as mining, construction, chemicals, and metallurgy, this grinding mill processes dolomite into powder for multiple uses. Its manual control system and semi-automatic operation provide users with a straightforward interface, while precision slide ways and large grinding wheel sizes enable accurate processing of various material volumes. The device can be tailored for specific requirements, including color and grinding mill type.

FAQs of Dolomite Grinding Mill Machine:

Q: How does the Dolomite Grinding Mill Machine operate for dolomite powder production?

A: The machine uses a high-speed rotating grinding wheel to crush and pulverize dolomite stones fed into it (25 mm in size), producing powder with adjustable fineness ranging from 80 to 400 mesh. Users can set working and spindle speeds to suit their processing needs, ensuring efficient grinding for a range of applications.Q: What industries typically use the Dolomite Grinding Mill Machine?

A: This grinding mill is mainly used in the mining, construction, chemical, and metallurgy industries. Its main purpose is to convert dolomite stone into fine powder for uses such as building material production, filler in chemical processes, and metallurgy applications.Q: When should I choose manual or automatic lubrication for the machine?

A: Manual lubrication offers simplicity for periodic use or straightforward maintenance routines, while automatic lubrication is ideal for demanding, continuous operations where consistent lubrication is crucial for reducing downtime and extending machine life. You can select either option based on your operational workflow.Q: Where can the machine be installed and how is it mounted?

A: The Dolomite Grinding Mill Machine is designed for floor-mounted installation, ensuring stability during operation. It requires a dedicated floor space of 3200 mm x 1500 mm x 2000 mm, making it suitable for factory floors or processing facilities in industrial environments.Q: What are the key safety features of the DGMM 3200 model?

A: The machine comes with comprehensive safety features, including an emergency stop button and protective guarding. These ensure safe operation for users by providing immediate shutdown in case of emergencies and shielding moving parts during grinding.Q: How does the mill benefit users in terms of efficiency and energy consumption?

A: With high grinding efficiency and low power consumption (powered at 37 kW), the Dolomite Grinding Mill Machine minimizes operational costs while maximizing output. Its semi-automatic functionality further streamlines the grinding process, enhancing productivity with minimal manual intervention.Q: What is the process for receiving and installing the machine upon order?

A: After placing an order, the machine is packed in a wooden box with standard export packing and dispatched from any major port in India. Upon arrival, on-site engineers or online support can assist with installation and setup to ensure optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese