Fine Powder Grinding Machine

Product Details:

- Model SG-250

- Rotation Clockwise

- Product Type Surface Grinder

- General Use Grinding fine powder materials for industrial applications

- Material Mild Steel

- Type Manual Surface Grinder

- Capacity 30 kg/hr

- Click to View more

Fine Powder Grinding Machine Price And Quantity

- 1 Unit

- USD ($)

- Up to 0.005 mm

- Floor mounted

- Integrated

- Wooden Crate

- Emergency stop, Overload protection

- Manual

- 50 mm

- Less than 70 dB

- Built-in

- On-site installation and training

- Industrial workshop

- Induction motor

- Automatic Pump

Fine Powder Grinding Machine Product Specifications

- Grinding fine powder materials for industrial applications

- No

- Mild Steel

- 3200 rpm

- Clockwise

- 2 HP

- 220/440 V

- Not CNC

- 500 mm

- 250 mm x 500 mm

- Double V-way

- 40 Liters

- SG-250

- 30 kg/hr

- 650 kg

- Manual Surface Grinder

- 2800 rpm

- 1500 mm x 1100 mm x 1700 mm

- 1500 mm x 1100 mm

- 180 mm x 13 mm x 31.75 mm

- Low noise, High precision

- No

- 250 mm x 500 mm

- Manual

- Surface Grinder

- Sky Blue

- Up to 0.005 mm

- Floor mounted

- Integrated

- Wooden Crate

- Emergency stop, Overload protection

- Manual

- 50 mm

- Less than 70 dB

- Built-in

- On-site installation and training

- Industrial workshop

- Induction motor

- Automatic Pump

Fine Powder Grinding Machine Trade Information

- 1000 Unit sets Per Month

- 15 Days

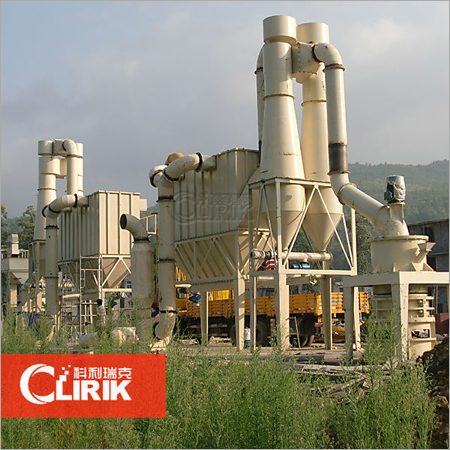

Product Description

We are a noteworthy manufacturer, supplier, trader and exporter of highly appreciated Fine Powder Grinding Machine. The offered grinding machine is well-equipped with various components that includes main unit, dust cleaner, powder collector, blower, muffler, classifier, hammer crusher (can be replaced by jaw crusher), vibrating feeder, sound-proof room, storage hopper, bucket elevator, and so on. Our offered Fine Powder Grinding Machine is highly acclaimed amongst customers for its various features like high safety, high efficiency and long life cycle of grinding machine spare parts.

Features :

- High Efficiency: Under the same finished final size and the same motor power, the capacity of fine powder grinding machine is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30%.

- Long life cycle of spare parts: The ring and roller are forged by special material with high utilization. Under the same grinding material and finish special size, the life cycle of spare parts is about one year, which is 2-3 times longer than impact mill or turbo mill. Furthermore, the lifetime can reach 2-5 years for grinding calcite carbonate.

- High safety and reliability: As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal components.

- High fineness, flexible adjustment: The final fineness of the grinding materials can be adjusted between 325 meshes and 2500 mesh (47-5 micron), and the product fineness can reach D9m.

- Environment-friendly: The application of pulse bag filter and muffler greatly alleviates dust pollution and noise.

- Advanced intelligent speed control device: Convenient adjusting, more uniform particle size.

Application :

There are five types of Shanghai CLIRIK fine powder grinding machine, they are HGM80, HGM90, HGM100, HGM100125 and HGM1680L. The finished production fineness can be reached 150 meshes~2500 meshes, 5-100 micron. The capacity (ton/hour) ranges from 0.4T/H to 30T/H. CLIRIK ore mineral crushing, screening, fine powder grinding machine has been exported to many countries which includes China, India, Pakistan, Malaysia, Vietnam, Thailand, Egypt, Nigeria, South Africa, Brazil, Canada, Columbia, Chile, Australia, Russia and so on.

Specification :

| Model | HGM80 | HGM90 | HGM100 | HGM125 | HGM1680L |

| Ring Diameter(mm) | 800 | 900 | 1000 | 1250 | 1680 |

| Ring Number (PCS) | 3 | 3-4 | 4 | 4 | 4 |

| Roller Number(PCS) | 18-21 | 24-29 | 28-36 | 30-44 | 30-40 |

| Main Shaft Speed (r. p. min) | 230-240 | 200-220 | 180-200 | 135-155 | 120-130 |

| Input Size (mm) | 10 | 10 | 15 | 15 | 20 |

| Finished Size (um/mesh) | 74-5 (200-2500) | 74-5 (200-2500) | 74-5 (200-2500) | 100-6 (150-2000) | 100-9 (150-1500) |

| Capacity (t/h) | 0.4-4.5 | 0.6-6.5 | 1-9 | 2-16 | 3.8-30 |

| Outlet Size L*W*H (m) | 13.9*4*6.2 | 14.7*4.8*7.2 | 18*4.6*8.6 | 14*9*10.25 | 26.3*7.5*11.9 |

Note : This specification is just referencing, any changes are subject to the products.

Precision Grinding for Industrial Demands

Engineered for fine powder grinding, the SG-250 offers exceptional accuracy and stability with its manual control system and robust construction. A finishing precision of up to 0.005 mm meets the stringent standards required in industrial applications.

Efficient and Safe Operation

This machine incorporates automatic lubrication, integrated dust collection, and a built-in coolant system, ensuring consistent performance with minimal maintenance. Safety is enhanced by emergency stop features and overload protection.

Designed for Practical Workshop Use

Floor-mounted and packed in a wooden crate, the SG-250 is tailored for use in industrial environments. Its low noise profile and reliable induction motor ensure a comfortable and productive workspace.

FAQs of Fine Powder Grinding Machine:

Q: How does the Fine Powder Grinding Machine ensure precise finishing accuracy?

A: The SG-250 is designed with a manual control system, double V-way table slide, and high-grade grinding wheel, delivering a finishing accuracy of up to 0.005 mm for fine powder materials in industrial settings.Q: What safety features are included in the Fine Powder Grinding Machine?

A: Safety is prioritized through integrated emergency stop and overload protection systems, making the machine safe for continuous use in workshop environments.Q: When is on-site installation and training provided for the SG-250 model?

A: On-site installation and training are offered upon delivery, allowing operators to become familiar with setup, operation, and maintenance procedures directly in their workshop.Q: Where is this grinding machine best utilized?

A: This manual surface grinder is ideally suited for industrial workshops, production facilities, or manufacturing plants requiring high precision fine powder grinding.Q: What process does the SG-250 use to manage dust and coolant?

A: The machine features an integrated dust collection system and built-in coolant mechanism, efficiently controlling particle dispersal and temperature during grinding tasks.Q: How does the operator control table movement and grinding operations?

A: All table movements and grinding functions are manually controlled, providing operators full tactile feedback and precise manipulation throughout the grinding process.Q: What are the benefits of choosing the SG-250 for industrial powder grinding?

A: Benefits include high precision, low noise operation, automatic lubrication, integrated dust and coolant management, reliable safety features, and support through on-site installation and training.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese