Calcium Hydroxide Grinding Mill Machine

Product Details:

- Rotation Clockwise

- Model HGM-80

- Product Type HGM

- General Use Grinding

- Material Galvanized Steel

- Type Feed Grinding Machine

- Computerized No

- Click to View more

Calcium Hydroxide Grinding Mill Machine Price And Quantity

- USD ($)

- 1 Unit

Calcium Hydroxide Grinding Mill Machine Product Specifications

- 45 kW

- Galvanized Steel

- 4800x2100x4500 mm

- HGM-80

- 180 mm

- No

- White & Blue

- 500 mm

- High Efficiency, Durable Finish, Low Maintenance

- 2850 RPM

- Clockwise

- 3200 RPM

- 250x500 mm

- 380 V

- Manual Panel

- 65 L

- Grinding

- Semi Automatic

- Not CNC

- Box Way

- Feed Grinding Machine

- 250x500 mm

- 1.8x2.2 m

- HGM

Calcium Hydroxide Grinding Mill Machine Trade Information

- Shanghai

- Cash Against Delivery (CAD), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- 1000 Unit Per Month

- 15 Days

- Wooden box

- All India

- CE&ISO

Product Description

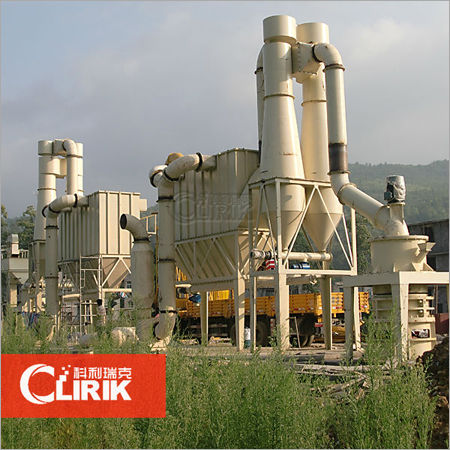

Calcium Hydroxide Grinding Mill Machine

Calcium Hydroxide Grinding Mill Machine is the equipment specializing in producing fine and superfine powder of noninflammable nonexplosive and brittle materials with Mohss hardness under six such as calcite chalk limestone dolomite kaolin bentonite talc mica magnesite illite pyrophyllite and vermiculite sepiolite attapulgite rectorite diatomite barite gypsum alunite graphite fluorite rock phosphate Kalium ore pumice etc totally more than 100 kinds of materials

Calcium Hydroxide Grinding Mill Machine made by Shanghai Clirik has the features of high efficiency environmental protection and energy consumption The powder are widely used as new building materials and chemical products of raw materials because of rich resource and low price getting the favor people At present our ultrafine mill ultrafine grinding mill not only has a large number of customers at home but also exported to dozens of countries abroadour ultrafine mill ultrafine grinding mill have exported to more than 130 countries such as USA UAE Ukraine Japan Poland France Brazil Mexico Germany Indonesia India Vietnam Philippines Canada South Africa Zimbabwe Russia and so on

Working Principle of Calcium Hydroxide Grinding Mill Machine

1 After crushed by hammer crusher the large materials become smaller pieces and are sent to the micro powder grinding mill

2 When the micro powder grinding mill is at work the granulated materials are crushed and grinded by the rollers into particles below 47micron

3 The highpressure air blower constantly inhales air within the micro powder grinding mill

4 Along with the high speed airflow micronized materials are brought to the classifier

5 The qualified particles are screened and driven into the cyclone powder collector finally exit from the discharging valve at the bottom

6 A small proportion of the fine powders with airflow moving to the dust cleaner Filtered clean air will be emitted from the air outlet of muffler in the end

Features and advantages of Calcium Hydroxide Grinding Mill Machine

l High efficiency

Under the same finished final size and the same motor power the capacity of stone micronizer is twice as much as jet mill mixing grinder and ball mill

2Long lifecycle of spare parts

The ring and roller are forged by special material with high utilization Under the same grinding material and finish special size the lifecycle of spare parts is about one year which is 23times longer than impact mill or turbo mill Furthermore the lifetime can reach 25 years for grinding calcite carbonate

3High safety and reliability

As no rolling bearings or screws in grinding cavity there are no problems caused by bolts shedding or rapid wear of bearings and seal components

4 High fineness and flexible adjustment

The final fineness of the grinding materials can be adjusted between 325 meshes and 3000 meshes and the product fineness can reach D975um

5Environmentfriendly

The application of pulse deduster and muffler greatly alleviates dust pollution and noise

Precise Powder Production

Achieve consistent calcium hydroxide powder with adjustable fineness ranging from 325 to 3000 mesh. The HGM-80 grinding mill ensures high processing accuracy, essential for various industrial applications. Its manual panel offers straightforward control, while the sturdy spindle and box way table support stable and precise grinding performance.

Efficient Design and Operation

Equipped with an efficient grinding wheel spinning at 2850 RPM and a table capacity of 250x500 mm, the HGM-80 is built for productivity. Clockwise rotation and a spacious feed dimension below 10 mm enable smooth operation, while the semi-automatic design simplifies workflow for operators.

Enhanced Safety and Low Noise

Work with peace of mind thanks to integrated cyclone and pulse dust collection systems, which minimize airborne particles during operation. The machine maintains a low noise level of under 75 dB, providing a safer and more comfortable workplace environment.

FAQ's of Calcium Hydroxide Grinding Mill Machine:

Q: How does the HGM-80 Grinding Mill achieve fine powder output between 325 and 3000 mesh?

A: The HGM-80 uses a high-speed grinding wheel (2850 RPM) and a robust box way slide table, ensuring precise and consistent grinding of calcium hydroxide powder to fine mesh sizes ranging from 325 up to 3000, suitable for various industrial applications.Q: What collection methods are used to control dust during operation?

A: This grinding mill combines a cyclone and a pulse dust collector to efficiently collect fine particles and reduce dust emissions during the grinding process, maintaining a clean and safe working environment.Q: When should the grinding wheel or fuel tank be checked or maintained?

A: It is recommended to inspect the 180 mm grinding wheel before each operation and perform regular maintenance according to the user manual. Check the fuel tank (65 L capacity) regularly and ensure it is adequately filled for uninterrupted operation.Q: Where is the grinding machine best installed in a production facility?

A: The machine requires a stable foundation and a floor space of at least 1.8x2.2 meters. Ensure installation in a well-ventilated area with access to a 380 V power supply for optimal performance and operator safety.Q: What are the main benefits of using the HGM-80 Calcium Hydroxide Grinding Mill?

A: Users benefit from high efficiency, durable construction, and low maintenance. The semi-automatic operation and manual panel controls provide operational flexibility, while after-sales support ensures reliable long-term use.Q: Is this machine suitable for computerized or CNC operation?

A: No, the HGM-80 features a manual control panel and is not designed for CNC or computerized control. This design prioritizes durability and straightforward operation for effective calcium hydroxide grinding.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese