Feldspar Grinding Mill Machine

Product Details:

- Model FGMM-1250

- Rotation Clockwise

- Product Type Feldspar Grinding Mill Machine

- General Use Grinding feldspar, quartz, and other minerals into fine powder for use in ceramics, glass, and industrial applications.

- Material Mild Steel, Cast Iron

- Type Surface Grinding Machine

- Capacity 300-800 kg/hr

- Click to View more

Feldspar Grinding Mill Machine Price And Quantity

- 1 Unit

- 9999 USD ($)

Feldspar Grinding Mill Machine Product Specifications

- Industrial Green & Silver

- FGMM-1250

- Mild Steel, Cast Iron

- 1250 x 260 mm

- Surface Grinding Machine

- 1440 RPM

- Double V type

- 2200 x 2000 x 1800 mm

- 2200 x 2000 mm

- 2600 kg

- Not CNC

- 7.5 kW

- Robust construction, Low maintenance, High efficiency

- Clockwise

- Semi Automatic

- Manual / PLC Based (Optional)

- 415 V / 380 V, 3 Phase

- 400 x 150 mm

- 180 x 13 x 31.75 mm

- Feldspar Grinding Mill Machine

- 750 mm

- 300-800 kg/hr

- 1440 RPM

- 40 liters

- No

- Grinding feldspar, quartz, and other minerals into fine powder for use in ceramics, glass, and industrial applications.

Feldspar Grinding Mill Machine Trade Information

- 1000 Unit Per Month

- 15 Days

Product Description

Models HGM80 HGM90 HGM100 HGM100A HGM125 and HGM1680

Power 1233444 kw

Finished size 3253000 meshes 547 micron

Raw materials calcite chalk limestone dolomite kaolin gypsum and talc etc totally more than 100 kinds of materials

Capacity 0545th

Max feeding size 20mm

Application mainly applied to grind noninflammable nonexplosive and brittle materials with Mohs hardness under six

Shipping ports Shanghai China

Delivery 15 days after received the deposit

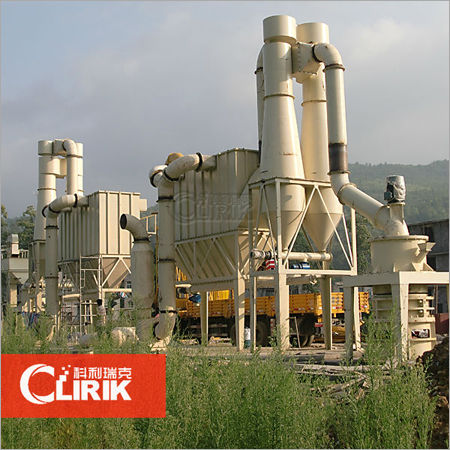

Feldspar Grinding Mill Machine is the new type mining equipment for making micro powders fine powderswhich is widely applied in the industries of metallurgy mining chemistry cement construction refractory materials ceramics and so onThe purpose of the micro powder grinding millis for superfine grinding materials with hardness less than 9 in Mohs scale and humidity less than 6 percent such as kaolin limestone calcite marble talcum barite gypsum dolomite bentonite mud mica pyrophyllite sepiolite carbon black diatomite graphite alunite fluorite potassium feldspar phosphorite pigment up to 200 kinds

Production line consists of hammer crusher bucket elevator storage hopper vibrating feeder main unit inverter classifier cyclone collector pulse deduster system high pressure positive blower air compressors and electrical control systems

Working Principle of micro powder grinding mill

When Feldspar Grinding Mill Machine is at work all the grinding rollers are rolling in the ring and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed crushed and grinded by the rollers

The highpressure air blower constantly inhales air within the grinding mill and in turn the airflow with crushed materials are brought to the classifier whose highspeed impeller will screen the airflow the unqualified particle size will fall and return to the mill for being reground while the qualified particle size mixed with air will go into the cyclone powder collector Most of the qualified powders will fall and exit from the discharging valve at the bottom a small proportion of the fine powders with airflow moves to the dust cleaner and clings to the surface of the filter bags At the same time the fine powders clinging to the surface fall down by the sudden vibration of the filter bags which is caused by the instantly ejected highpressure gas controlled by the pulse valve The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed In addition filtered clean air will be emitted from the air outlet of muffler in the end

Robust Engineering for Diverse Applications

The FGMM-1250 Feldspar Grinding Mill Machine is optimized for processing minerals across various industries, including ceramics, glassmaking, paint, and refractory material production. Its durable steel and cast iron construction ensures longevity, even in heavy-duty industrial environments. The machines low noise output and integrated coolant system provide a comfortable, efficient workspace.

Precision Performance and Control

Featuring manual or optional PLC-based controls, the FGMM-1250 allows operators to precisely control grinding parameters. The heavy-duty ball bearing-supported main shaft and double V-type table slide way enhance operational stability, yielding consistent powder fineness (80400 mesh) and surface finish. The optional dust collector attachment helps maintain a clean processing environment.

FAQs of Feldspar Grinding Mill Machine:

Q: How does the Feldspar Grinding Mill Machine achieve fine powder output?

A: The FGMM-1250 uses a high-speed grinding wheel and precise control over the main shaft speed (230 r/min), allowing for consistent grinding of minerals like feldspar and quartz into powder grades between 80 and 400 mesh. Its robust build and efficient coolant system further optimize particle size distribution and surface quality.Q: What industrial sectors can benefit from using this grinding mill machine?

A: This machine is suitable for a variety of industries, including ceramics, glass, paint, electrode manufacturing, and refractory materials processing. Its ability to efficiently pulverize minerals makes it indispensable wherever fine mineral powders are in demand.Q: When is it necessary to use the dust collector attachment?

A: The optional dust collector is recommended when grinding operations produce a significant amount of airborne particles, especially in enclosed spaces or facilities that require high air quality standards. This helps protect workers and equipment from dust accumulation.Q: Where can the Feldspar Grinding Mill Machine be installed?

A: Due to its substantial floor space requirements (2200 x 2000 mm) and robust construction, the machine is best installed in industrial workshops or factories equipped with 3-phase power. Adequate ventilation and clearance around the unit are advised for safe operation and maintenance.Q: What is the process for controlling the grinding operations?

A: Operators can use either manual controls or upgrade to a PLC-based control system for automated management. The process involves feeding materials (<20 mm), adjusting settings for the desired fineness, and monitoring key parameters such as spindle speed and coolant flow throughout the grinding cycle.Q: How do users benefit from the FGMM-1250 models features?

A: Users gain from high efficiency (up to 800 kg/hr), robust design, and low maintenance requirements. The combination of a heavy-duty ball bearing system, efficient power consumption, and customizable grinding options delivers reliable performance for high-volume and high-precision mineral grinding tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+