Cement Ball Mill

Product Details:

- Model CBM Series

- Rotation Horizontal

- Product Type Ball Mill

- General Use Cement, Construction, Mining Industries

- Material Mild Steel / Alloy Steel

- Type Grinding Mill

- Capacity 15-200 TPH (varies per model)

- Click to View more

Cement Ball Mill Price And Quantity

- USD ($)

- 1 Unit

- 16-50 mm

- Overflow or Grate

- Slide or Rolling Bearings

- Gear/Girth Gear Driven

- Up to 25 rpm

- Manganese Steel / High Chrome Steel

- Fixed/Stationary

- Continuous

- Clinker, Raw Material, Coal, Slag Grinding

- 25-50 mm

- 0.074-0.4 mm

- Less than 85 dB

- AC Motor

- Air/Water Cooled

Cement Ball Mill Product Specifications

- Blue / Green / Customized

- Low, 18-25 RPM

- 15-200 TPH (varies per model)

- 60,000 - 250,000 kg (varies by size)

- Not CNC

- CBM Series

- Grinding Mill

- Heavy-duty

- 100-1500 kW (varies per model)

- Mild Steel / Alloy Steel

- 380-415 V, 3 Phase

- Robust, Energy Efficient, Long Service Life

- Varies with model (e.g. 30 x 12 m)

- No

- Manual or Automatic

- Semi-Automatic or Fully Automatic

- Up to 13 meters

- 18-25 RPM

- Cement, Construction, Mining Industries

- Horizontal

- Ball Mill

- Customized

- Customizable as per design

- Customizable

- 16-50 mm

- Overflow or Grate

- Slide or Rolling Bearings

- Gear/Girth Gear Driven

- Up to 25 rpm

- Manganese Steel / High Chrome Steel

- Fixed/Stationary

- Continuous

- Clinker, Raw Material, Coal, Slag Grinding

- 25-50 mm

- 0.074-0.4 mm

- Less than 85 dB

- AC Motor

- Air/Water Cooled

Cement Ball Mill Trade Information

- Shanghai

- 1000 Unit Per Month

- 15 Days

- Wooden Box Packing.

- ISO 9001:2008

Product Description

Cement Ball Mill

- Capacity:20-200 T/H

- Feeding size:25 Mm

- Output Size:30-400 Mesh

Brief Introduction of Cement Ball Mill

Cement Ball mill can divide into 2 types, wet ball mill grinding and dry ball mill grinding. Ball mill grinding is a mineral processing machine for milling the materials into powders after they are crushed.

Features of Cement Ball Mill:

2. The shape of the final products is circular

3. No pollution for the powder with ceramic ball

4. Stable performance

5. Easy installation

6. The capacity and fineness can be adjusted by adjusting the diameter of the ball

Working principle of Cement Ball Mill:

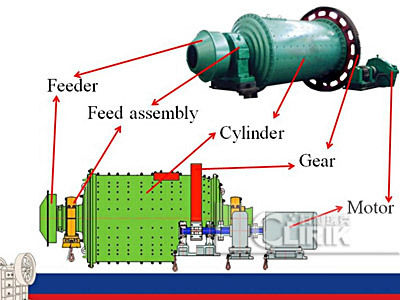

Ball mill grinding is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and rippleliner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Robust Design and Construction

The Cement Ball Mill is constructed using high-quality mild steel or alloy steel, with shell thickness ranging from 16 to 50 mm. Its heavy-duty liner options in manganese or high chrome steel deliver superior wear resistance, while fixed installation supports high operational stability in demanding environments.

Energy Efficient Performance

Equipped with powerful AC motors and an optimized girth gear-driven transmission, the CBM Series ensures energy-efficient grinding for clinker, raw materials, coal, and slag. Its air or water cooled systems maintain optimal temperatures, while advanced bearing choices minimize friction for longer service life.

Flexible Operation and Customization

Customizable table size, grinding wheel dimensions, and discharge methods give users control over output quality. Whether used in cement, mining, or construction, the mills continuous feeding and manual or automatic controls enable tailored operation for varied production requirements.

FAQs of Cement Ball Mill:

Q: How does the Cement Ball Mill handle different raw materials?

A: The Cement Ball Mill CBM Series is designed to efficiently grind clinker, raw materials, coal, and slag using its robust shell and durable liner materials. Its continuous feeding system and customizable inlet size accommodate various material types and sizes.Q: What are the benefits of using manganese steel or high chrome steel liners?

A: Manganese steel and high chrome steel liners provide excellent resistance to abrasion and impact inside the mill. This results in extended service life, reduced maintenance needs, and consistent grinding performance even when processing hard or abrasive materials.Q: When should I choose overflow versus grate discharge for my application?

A: Overflow discharge is preferable for fine grinding tasks with moderate throughput, while grate discharge is recommended where higher capacity and quicker removal of ground material are crucial. Selection depends on the desired product size and processing requirements.Q: Where can the Cement Ball Mill be installed?

A: The mill is designed for fixed installation at cement plants, construction sites, or mining facilities. Its customizable dimensions and robust structure allow it to be tailored for diverse site requirements and space constraints.Q: What is the operational process of the CBM Series Cement Ball Mill?

A: Raw materials are continuously fed into the horizontal drum, where rotating grinding wheels process them to the specified discharge size. The motor-driven system and cooling mechanism ensure efficient operation, while manual or automatic controls enable precise management.Q: How does the mills energy efficiency contribute to overall operational savings?

A: Energy efficiency is achieved through optimized drive systems, high-quality bearings, and cooling solutions that reduce power consumption and minimize wear. This lowers operational costs and boosts long-term reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese