Ball Mill Plant

Product Details:

- Model Available in various models

- Rotation Continuous 360

- Product Type Ball Mill

- General Use grinding

- Material Mild Steel / Stainless Steel as required

- Type Feed Grinding Machine

- Capacity 500 kg/hr - 10 ton/hr

- Click to View more

Ball Mill Plant Price And Quantity

- USD ($)

- 1 Unit

Ball Mill Plant Product Specifications

- Depends on capacity (approx. 15 x 8 ft or more)

- Manual

- No

- Semi-Automatic / Automatic options available

- Customizable as per design

- Custom built, varies with capacity

- Variable, 1838 rpm

- Varies by model, 215 tons

- Customizable

- Not Applicable (electric driven)

- 380 V / 415 V, 3 phase

- No

- Mild Steel / Stainless Steel as required

- Ball Mill

- As per design, e.g., 12 x 7 x 7 ft

- grinding

- Available in various models

- Variable, up to 60 Hz

- High efficiency, robust construction, easy maintenance

- 500 kg/hr - 10 ton/hr

- Continuous 360

- 30125 kW depending on size

- Feed Grinding Machine

- Customized (generally Blue/Green/Grey)

- Heavy-duty slide way

Ball Mill Plant Trade Information

- Shanghai

- 1000 Unit Per Month

- 15 Days

- Wooden box

- Africa, Middle East, Asia

- All India

- ISO 9001:2008

Product Description

Ball Mill Price

Classification of Energy-saving Ball Mill:

Energy-saving ball mill for grinding various ores and other materials, are widely used in mineral processing, building materials and chemical industry can be divided into dry and wet grinding. According to different ways of discharge can be divided into the two types---lattice type and overflow type.

Application of Energy-saving Ball Mill:

Energy-saving ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Features of Energy-saving Ball Mill:

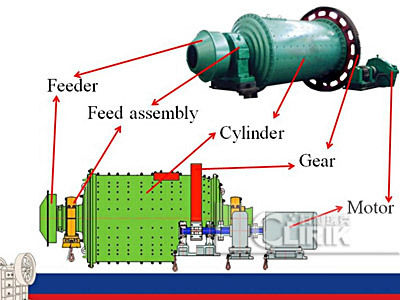

The main parts of the energy-saving ball mill are feeding part, discharging part, turning part, and transmission parts (reducer, small transmission gear, motor, electric control). The hollow axis adopts the cast steel, lined with removable, rotary gear adopts casting hobbing process, the body inlaid cylinder liner wear, has good wear resistance. The machine is running smoothly, working reliably.

Energy-saving ball mill changes the intrinsic grinding machine structure. Its body and ground plank are an integral whole. So when fixing, it can be lowered on a plane surface once only. Use double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30%. The intrinsic grille pattern forcing evacuation is instead by over fall pattern controlling one. This can improve the milling of the granule and the quantity dealt with is reduced by 15-20%.

Working principle of Energy-saving Ball Mill:

The energy-saving ball mill is a horizontal cylindrical rotating device, outer gear, the two positions, lattice energy-saving ball mill. Material from the feed device into the compound empty-axis spiral evenly into the mill first warehouse, the warehouse there are ladder liner or corrugated liner, built with different specifications steel ball, rotating cylinder produces centrifugal force to the ball a certain height after the fall, have severe impact on the material and abrasive. Material in the first position, the coarse grinding, single-compartment plate into the second warehouse, the warehouse lined with flat lining, the steel ball, the material further grinding. Powder discharged through the discharge grate plate to complete the grinding operation.

Robust Construction and Customizable Options

The Ball Mill Plant is engineered with a choice of heavy-duty mild steel or stainless steel drum materials and multiple liner configurations, including manganese steel and rubber. Models are available in various sizes to suit throughput requirements, with configurable feeding and discharge sizes. Customization for table size, grinding length, and color ensures suitability for any industrial setting or process specification.

Optimized Performance for Multiple Industries

Ideally suited for grinding operations in cement, mineral processing, paints, and the chemical industry, our Ball Mill Plant provides efficient and uniform grinding due to its continuous 360 rotation and variable grinding speeds. High efficiency, easy maintenance, and an automatic centralized lubrication system contribute to reliable operation with minimized downtime.

Certified Quality, Service, and Support

Certified to ISO 9001:2015 standards, the Ball Mill Plant includes standard export-ready packing, installation services, on-site and remote after-sales support. Low-noise design, compliance with industrial safety, and electric drive options make it suitable for global markets. Ports of dispatch and specifications can be customized as per buyer requirements, ensuring seamless delivery and setup.

FAQ's of Ball Mill Plant:

Q: How does the Ball Mill Plant process materials and achieve fine grinding results?

A: The Ball Mill Plant uses heavy-duty steel or stainless steel drums filled with steel, ceramic, or forged balls. Material is fed up to 25 mm in size and, through continuous rotation and impact, is ground down to fine particles as small as 0.074 mm (200 mesh). Adjustable speed and liner selection optimize grinding efficiency and product quality for various applications.Q: What industries and materials are suitable for processing in this Ball Mill Plant?

A: The Ball Mill Plant is suitable for the cement industry, mineral processing, paints, and chemical industries. It can efficiently grind hard and abrasive materials into fine powders or slurries, making it ideal for diverse industrial sectors needing precision and high-capacity grinding solutions.Q: When should I choose manganese steel, rubber, or other liner materials for my application?

A: Liner choice depends on the processed material and desired wear resistance. Manganese steel liners are ideal for grinding abrasive, hard minerals, offering maximum durability. Rubber liners are preferred for less abrasive materials, providing quieter operation and simpler maintenance. The right liner enhances lifespan and operational efficiency.Q: Where and how is the Ball Mill Plant installed and commissioned?

A: We offer complete installation services at your site. Our technical team handles setup, alignment, and commissioning according to your facility's layout and capacity needs. Standard export packing ensures safe global shipping, with ports of dispatch arranged as per the buyer's requirements.Q: What is the benefit of the centralized automatic lubrication system?

A: The centralized automatic lubrication system continuously delivers precise lubrication to all critical moving parts, reducing wear, minimizing maintenance, and enhancing the Mill Plant's operational life and reliability. This feature ensures smooth, consistent performance with less downtime.Q: How does the Ball Mill Plant ensure safety and ease of maintenance?

A: Engineered with robust construction, low-noise operation, and a manual control system, the Ball Mill Plant prioritizes user safety. Easy access points and modular component design facilitate inspection, cleaning, and maintenance, reducing overall downtime and maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese